MARUB SA, Romania - Painting, Ventilation, and Filtration

Established in 1895 as “Atelierele de Locomotive si Vagoane Brasov,” MARUB SA was acquired in 2012 by the private passenger rail transport operator RC-CF TRANS Brasov.

Following the acquisition, an extensive development program was launched to transform MARUB SA from a local company into a major player on the national and regional markets.

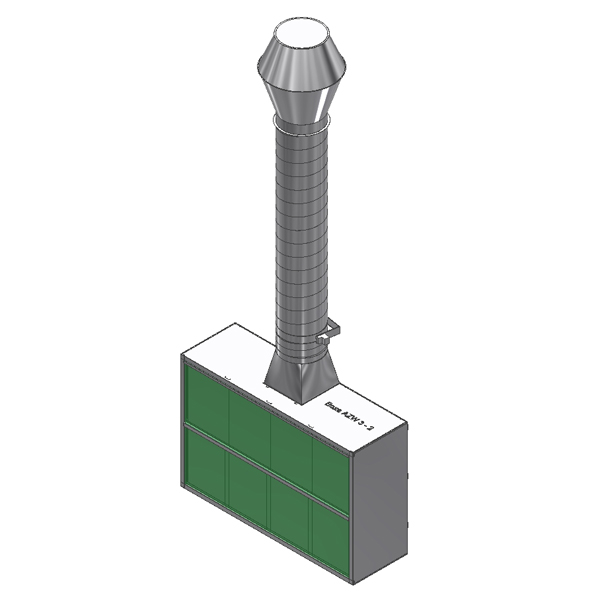

In 2013, Minex Group modernized and equipped the painting and drying hall at MARUB SA, delivering heating and exhaust units, an electric panel, ductwork, and other related equipment. This investment is part of a new repair and maintenance section for railcars and locomotives, which includes the most advanced European asbestos decontamination center for railway materials.

The implemented solutions delivered multiple benefits:

- Process efficiency: The modernization of the painting and drying hall enabled precise control of temperature and airflow, ensuring uniform paint application and faster drying times.

- Increased productivity: The new equipment reduced processing times, allowing for greater operational capacity and more efficient handling of complex projects.

- Energy efficiency: Modern heating and exhaust units contribute to lower energy consumption, reducing operational costs.

- Improved working conditions: The ventilation and filtration systems create a safer working environment by reducing workers’ exposure to hazardous particles and improving air quality within the hall.

- Environmental protection: Advanced technologies in the exhaust and filtration equipment significantly reduce pollution, ensuring sustainable waste management and compliance with environmental standards.

Through this modernization, MARUB SA has taken a significant step toward strengthening its position in the railcar and locomotive repair and maintenance market, demonstrating its commitment to performance, safety, and sustainability.