Cummins Generator Technologies SA, Romania - Painting

Minex Group enhanced the production processes of Cummins Technologies by designing and installing high-performance painting and drying booths, optimizing operational efficiency and reducing environmental impact.

Delivered Equipment and Solutions

1. Painting and Drying Booths: Two booths measuring 6 x 5 x 5 m, designed to provide a controlled environment and ensure consistent results in the painting and drying processes.

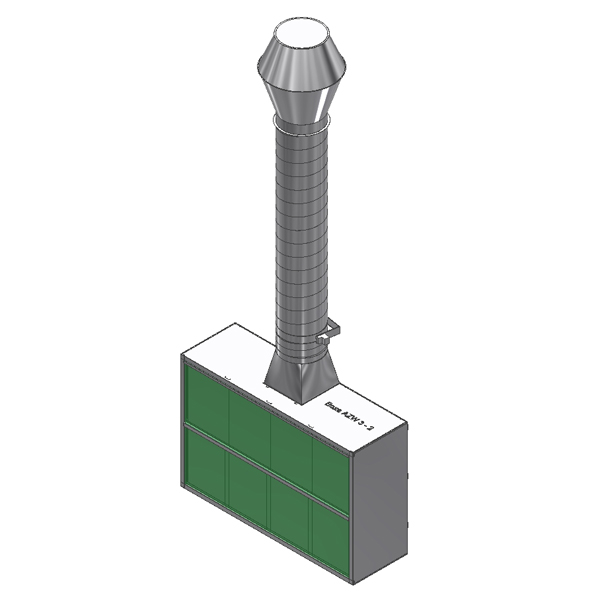

2. AZW Fume Extraction Units: Advanced systems for capturing and filtering fumes generated during painting, improving air quality in the workspace.

3. UHR Heater: An energy-efficient heating system that maintains optimal temperature in the painting and drying booths, contributing to reduced energy consumption.

Achieved Benefits

- Process Efficiency: The modern booths and associated equipment significantly reduced painting and drying times, increasing production speed.

- Increased Productivity: Advanced technologies enabled high-quality finishes to be achieved in shorter times, boosting production capacity.

- Improved Working Conditions: The fume extraction systems created a safer and more comfortable environment for operators, minimizing exposure to harmful substances.

- Environmental Protection: Reduced fume emissions and efficient resource utilization contributed to minimizing the environmental impact.

The Cummins Technologies project showcases Minex Group’s expertise in delivering customized technological solutions that improve process performance and support sustainability in the manufacturing industry.

Other References