Confind SRL, Romania - Blasting and Painting

Minex Group enhanced the efficiency and sustainability of Confind SRL’s operations by modernizing its anti-corrosion protection section. The delivered solutions were designed to improve process quality, productivity, working conditions, and environmental sustainability.

Delivered Equipment and Solutions

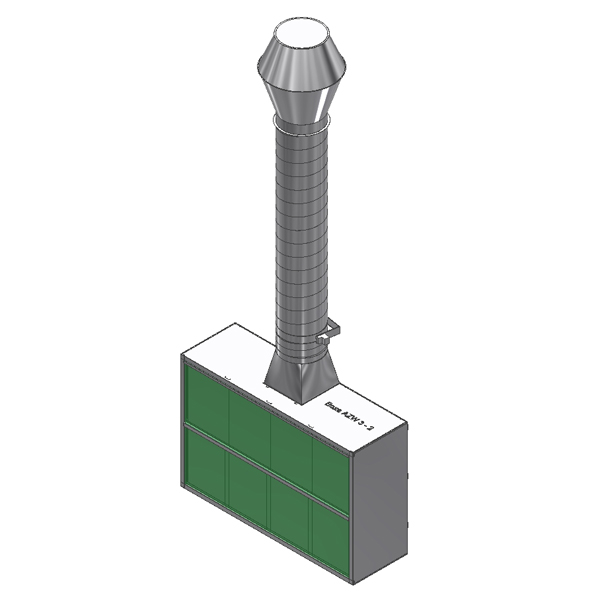

1. Blasting Booths: Ensure uniform and precise cleaning of metal surfaces, preparing them for the application of anti-corrosion protective layers.

2. Painting and Drying Booths: Provide a controlled environment for paint application and fast drying, ensuring superior adhesion and high-quality finishes.

3. Automated Roller Conveyor Blasting Line: Automates the blasting process, enabling rapid handling of materials of various sizes and reducing manual intervention.

Achieved Benefits

- Process Efficiency: Automating blasting and painting significantly reduced processing times, improving workflow and eliminating bottlenecks.

- Increased Productivity: High-performance equipment supports greater production volumes while maintaining quality standards and meeting delivery deadlines.

- Improved Working Conditions: Specially designed booths minimize operator exposure to dust and toxic fumes, ensuring a safer and more comfortable work environment.

- Environmental Protection: Integrated systems reduce dust emissions and resource consumption, supporting sustainability initiatives.

The Confind SRL project highlights Minex Group’s ability to deliver modern technological solutions tailored to specific client needs, fostering efficient and sustainable industrial processes.

Other References