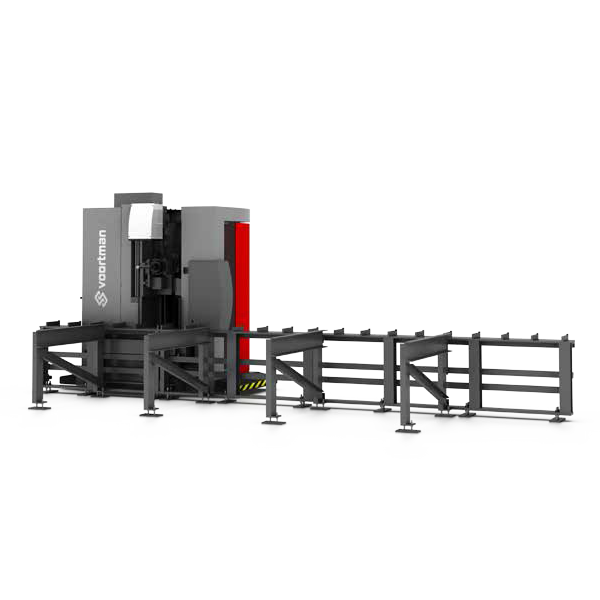

Voortman V600 - Beam Drilling System

The Voortman V600 Beam Drilling System is a compact yet powerful solution designed for structural steel fabricators and manufacturers with limited workshop space. Its small footprint is achieved through a movable cabin and an innovative drilling table available in multiple lengths to match specific customer needs. Unlike traditional systems requiring extensive cross transports and roller conveyors, the V600 reduces space requirements by 50%. Despite its compact design, the V600 offers versatile functionality, capable of processing a wide range of profiles, including I-beams, H-beams, channels, flat bars, angle irons, T-bars, square tubes, and rectangular tubes. Profiles that are already assembled can also be processed without requiring manual programming. This flexibility ensures increased productivity and a higher return on investment.

The system integrates advanced features such as a laser for full profile measurement to reduce mistakes, hydraulic clamps for vibration-free operation, and an onboard compressor for streamlined processing. Equipped with an automatic tool changer with five stations, the V600 allows for seamless operations like drilling, thread-tapping, countersinking, and centerpoint marking, all while maintaining efficiency and accuracy.

The integration of the Voortman V600 Beam Drilling System into your workshop can lead to significant improvements in productivity, process efficiency, and product quality, while reducing manual labor and operational costs.

Contact us today to discover how the Voortman V600 can transform your profile drilling and milling operations!