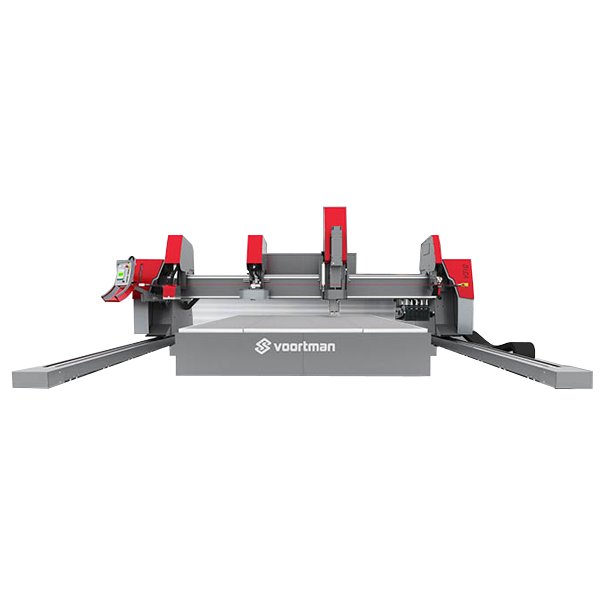

Voortman V325 - Heavy Plate Drilling, Cutting and Milling Machine

The Voortman V325 is a high-performance drilling, cutting, and milling machine designed for heavy plate processing. With its powerful SK50 / CAT50 drilling head and 20-station automatic tool changer, this machine is capable of processing thick plate steel up to 100 mm (4”) and drilling holes up to 70 mm (2-3/4”). Compared to conventional milling processes, the V325 significantly reduces production time and enhances automation. Advanced features such as automatic part removal, automatic deburring, 3D plasma bevel cutting, and oxy-fuel 4.0 cutting increase efficiency and streamline operations, making it an essential asset for high-volume production facilities.

Specification and Technical Data:

- Drilling diameter: up to 70 mm (2-3/4”).

- Plate thickness capacity: up to 100 mm (4”).

- SK50 / CAT50 high-torque spindle (610 Nm).

- Dual 10-station tool changers (20 tools total).

- 3D plasma bevel cutting and oxy-fuel torch.

- Automatic underside deburring unit.

- Automatic part removal conveyor.

- VACAM control software with Instant Cut Technology.

Take your production to the next level with the Voortman V325. Designed for precision, efficiency, and automation, this machine ensures top-tier performance for heavy plate drilling, cutting, and milling. Contact us today to learn more about how the Voortman V325 can revolutionize your manufacturing process.