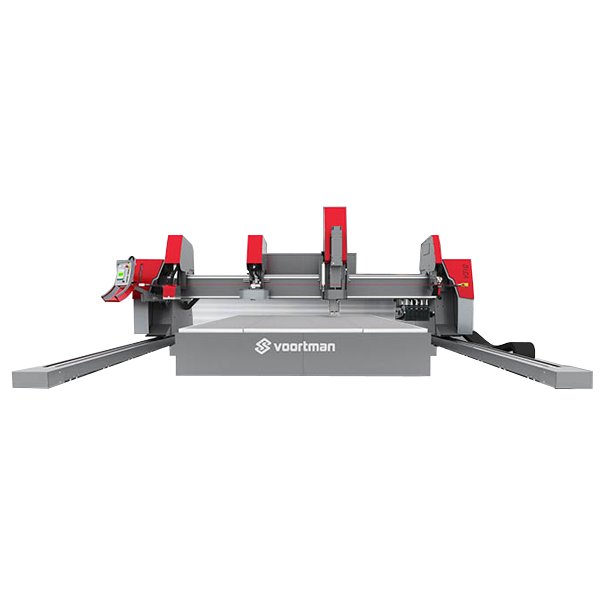

Voortman V320 - combined plate cutting and drilling

The Voortman V320 is a high-performance plate processing machine designed to maximize productivity through automation and efficiency. Engineered for uninterrupted operation, it integrates advanced workflows with a robust dropdoor table, a wide conveyor belt, and automatic chip removal, minimizing manual intervention. With its innovative gripper system, the V320 allows cutting close to the grippers, optimizing material utilization and reducing waste. The combination of automated unloading, HD Multidrop technology, and efficient nesting techniques ensures a streamlined and cost-effective production process, making it an ideal solution for modern metal processing facilities.

Specifications and Technical Data

- Automated unloading of parts up to 500x500 mm (20"x20"), weighing up to 75 kg (165 lbs).

- Advanced nesting techniques to reduce waste and optimize material yield.

- HD Multidrop functionality for superior material utilization.

- Dual gripper trucks for precision plate movement.

- 10-station automatic tool changer for prolonged unmanned operation.

- Wide conveyor belt (750 mm) for efficient material handling.

- Integrated swarf brush for automated chip removal.

- Fastest height control technology for improved cutting efficiency.

- High-torque spindle for drilling up to 40 mm and thread tapping up to M30.

- Oxy-fuel and plasma cutting with seamless transitions.

- TrueVolt Technology for precise arc voltage control.

Boost your productivity and take your manufacturing process to the next level with the Voortman V320. Designed for efficiency, precision, and cost savings, this cutting-edge machine is the key to optimizing your operations and maximizing output.

Contact us today to learn more about how the Voortman V320 can transform your production capabilities and give you a competitive edge.