LAUCO Shot blasting machine with roller conveyors

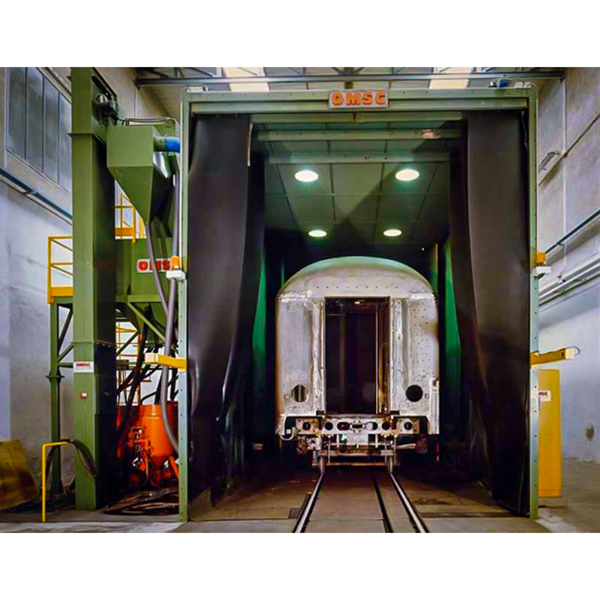

The LAUCO Shot Blasting Machine is a high-performance surface treatment solution designed for continuous cleaning and preparation of steel plates, sections, pipes, and structural components. Equipped with a tunnel chamber and powered by driven roller conveyors, the machine ensures efficient and thorough cleaning in a single pass, adhering to ISO 8501-1 and SIS SS 055900 standards.

Key Features of the LAUCO Shot Blasting Machine

Efficient Cleaning Process

- Workpieces are transported through the blast chamber on driven roller conveyors, tailored to the size and specifications of the components.

- Single-pass cleaning ensures uniform results and meets international quality standards.

- Brushing and blowing systems at the exit remove residual abrasive for a clean, ready-to-use finish.

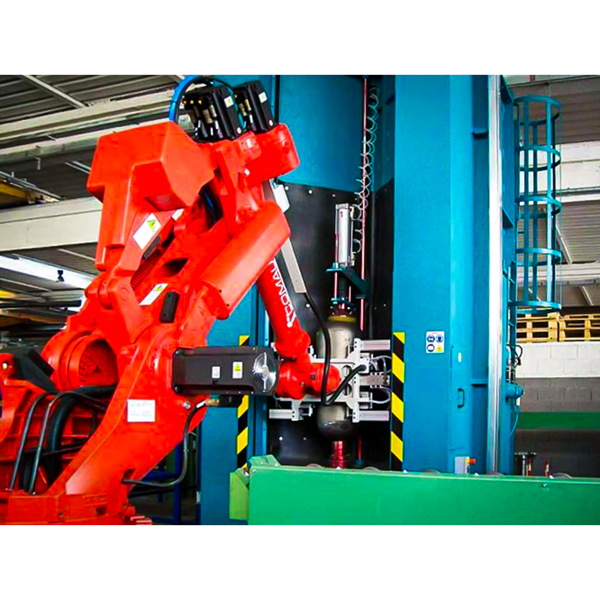

Customizable Configurations

OMSG offers a wide range of LAUCO Shot Blasting Machines to meet diverse industrial needs:

- Machines for Steel Plates and Sections: Designed for large-scale cleaning of plates and profiles.

- Internal and External Pipe Cleaning: Specialized for pipes, featuring shaped roller conveyors for precise handling.

- Machines for Structural Steel Work and Fabrications: Equipped with multiple blast wheels angled for optimal coverage.

- In-Line Machines with Painting Systems: Integrated blasting and painting lines for high productivity.

- Billet Descaling Machines: Featuring grooved roller conveyors for billets with square or round sections.

- Aluminum Extrusions and Profiles: Surface treatment for extruded aluminum, preparing for painting or machining.

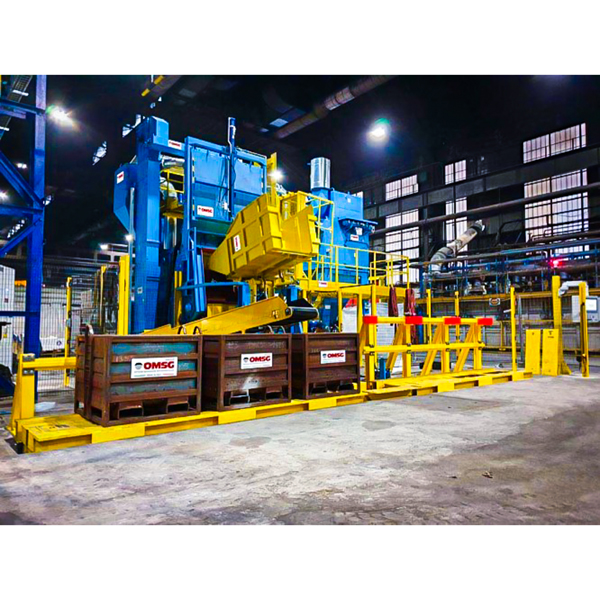

Advanced Options

- Heavy-duty roller conveyor for handling large and heavy components.

- External recovery hopper for efficient shot material management.

- Cross transfer loading/unloading systems to streamline workflow.

- Automatic wheel speed adjustment via frequency electronic control (Inverter) for precision and efficiency.

- Variable shot valve delivery for optimized abrasive flow control.

- Advanced control system with PLC Siemens S7-1200 and HMI touch screen interface (TP700 COMFORT) for intuitive operation.

- Digital turbine ampere control for performance monitoring and energy optimization.

Applications

The LAUCO Shot Blasting Machine is suitable for a variety of applications, including:

- Steel Plates and Profiles: Cleaning hot-rolled plates, beams, and structural steel.

- Pipes and Tubes: Internal and external surface preparation.

- Billets and Coils: Descaling and oxide removal.

- Aluminum Extruded Profiles: Preparation for painting, machining, and finishing.

Integrated Solutions

For combined blasting and painting operations, the LAUCO system can be part of a complete line including:

- Loading cross transfer systems.

- Pre-heating oven.

- Painting booths and drying ovens.

- Unloading cross transfer systems for rapid discharge.

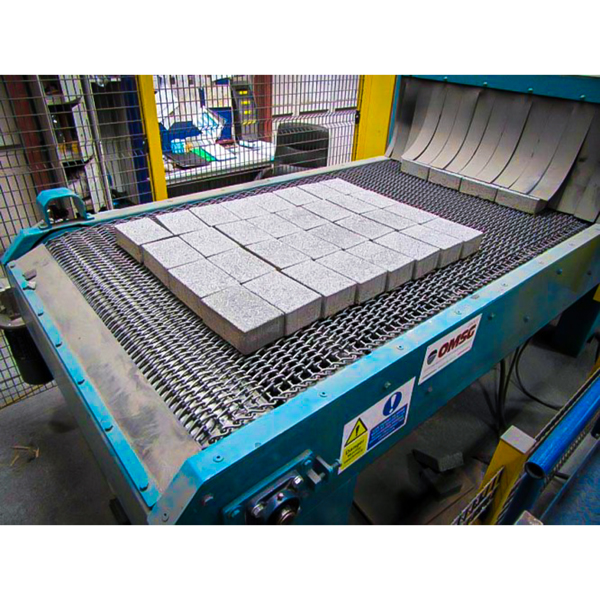

Examples of Treated Products

- Profiles and hot-rolled plates.

- Rolled and welded beams.

- Steel structural components.

- Pipes and tubes.

- Billets and coils.

Why Choose the LAUCO Shot Blasting Machine?

- Efficiency and Productivity

- Continuous operation and customizable conveyor lengths ensure high throughput.

- Integrated brushing and blowing systems reduce post-treatment cleaning efforts.

- Flexibility

- Wide range of machine types and configurations tailored to specific industries and production needs.

- Durability and Reliability

- Heavy-duty construction and advanced wear-resistant components ensure long-term performance.

- Scalable and Adaptable

- Configurable options and integration with painting lines make the LAUCO machine suitable for diverse production environments.

Contact Us

Discover how the LAUCO Shot Blasting Machine can transform your surface treatment process. Contact us today for customized solutions and expert advice!