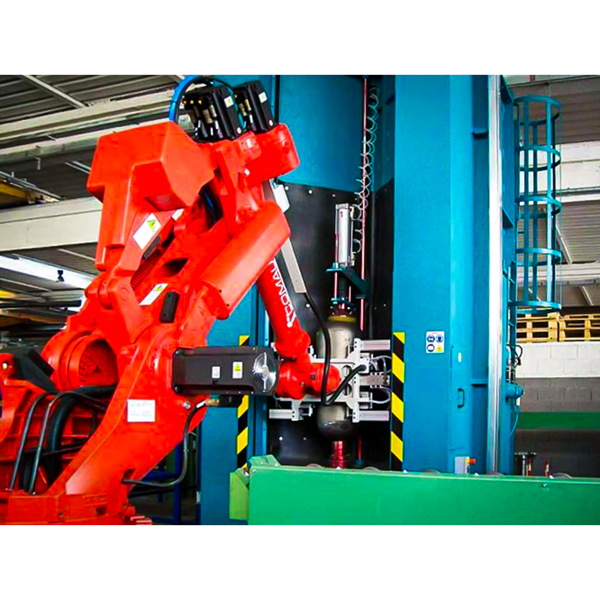

CAPRI Hook shot blasting machine

The CAPRI Hook Shot Blasting Machine is a highly versatile and efficient solution for surface treatment, suitable for a wide range of applications. Its innovative design allows workpieces to be hung individually or collectively on hooks, ensuring complete and thorough blasting of all surfaces. With a broad range of models and configurations, the CAPRI machine can meet the specific needs of any industry.

Key Features of the CAPRI Hook Shot Blasting Machine

Flexible Operating Principle

- Workpieces are suspended on hooks that move and rotate inside the blast chamber.

- Hooks expose all surfaces of the workpieces to the abrasive action from strategically positioned wheels, patented by OMSG.

Wide Range of Configurations

The CAPRI series includes various handling and loading systems to accommodate different workpiece sizes and weights:

Manual Handling (CAPRI M):

- For light workpieces.

- Standard load capacity: 300 - 1,000 kg.

Chain Handling (CAPRI C):

- Chain-driven system for easy movement of hooks inside the machine.

- Standard load capacity: 500 - 1,000 kg.

Chain + Hoist (CAPRI CS):

- Combined system for medium to large workpieces.

- Standard load capacity: 1,000 kg.

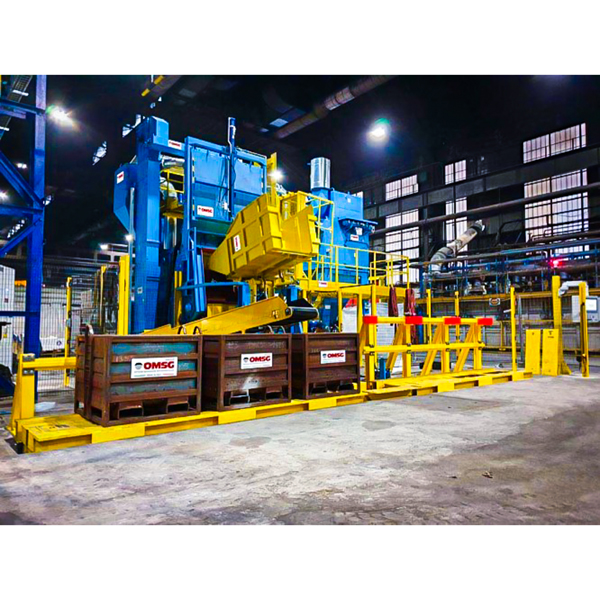

Hoist Handling (CAPRI H):

- Hoist systems for handling and lifting heavier pieces.

- Standard load capacity: 2,000 to 5,000 kg (up to 16,000 kg or more for custom fabrications).

Customizable Options

OMSG offers over 80 CAPRI models and specializes in custom installations tailored to specific customer requirements. Variations include:

- Blast chamber dimensions.

- Handling system type and load capacity.

- Number and power of blast wheels.

For specialized applications, CAPRI machines can be equipped with overhead crane systems and additional devices such as vibrating screens and magnetic separators for foundry operations.

Applications

The CAPRI Hook Shot Blasting Machine serves a wide range of industries, with models tailored to different applications:

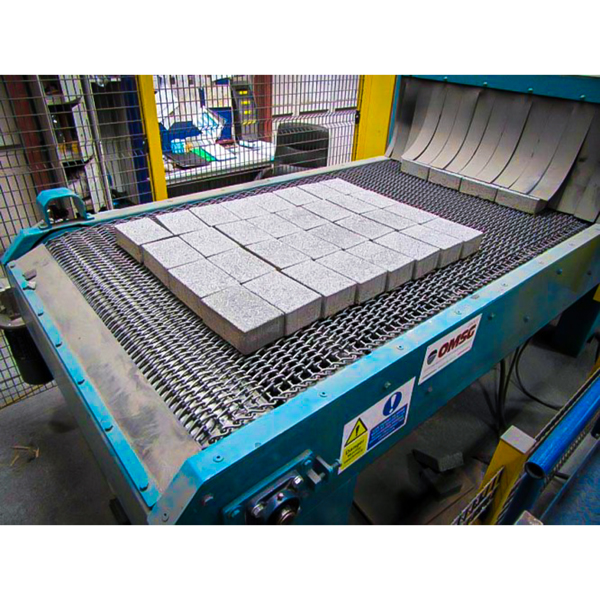

- Smaller Machines:

- Aluminum die-castings.

- Magnesium castings.

- Small steel fabrications.

- Gears and technological treatments.

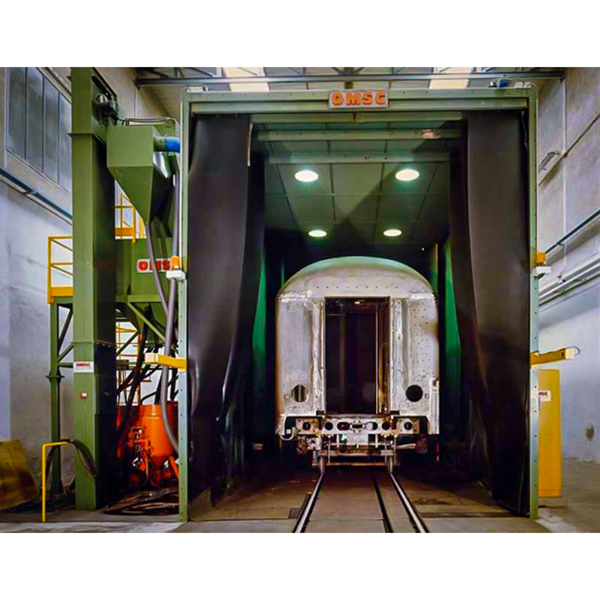

- Medium/Large Machines:

- Forges and foundries.

- Steel structures.

- Gears.

- Heat-treated components.

- Electric transformers.

Advanced Options

- Automatic wheel speed adjustment via frequency electronic control (Inverter).

- Shot valve with variable delivery for precise abrasive flow control.

- Advanced control system featuring PLC Siemens S7-1200 and intuitive HMI touch screen interface (TP700 COMFORT).

- Hoist systems for improved handling of heavy workpieces.

- Teleassistance for remote diagnostics and support.

- Digital turbine ampere control for optimized performance monitoring.

- Single-hoist versions with increased weight capacities (5,000 kg to 10,000 kg or more).

Benefits of the CAPRI Hook Shot Blasting Machine

- Efficiency and Precision

- Patented wheel positioning ensures uniform blasting on all surfaces.

- Versatile configurations allow for optimal performance across diverse applications.

- Flexibility

- Multiple handling systems accommodate workpieces of various sizes and weights.

- Customizable options make CAPRI machines suitable for unique production requirements.

- Durability and Reliability

- High-quality construction and advanced engineering ensure long-term performance and minimal maintenance.

- Scalable Solutions

- From light to heavy-duty models, CAPRI machines cater to both small-scale and industrial-scale operations.

Why Choose CAPRI?

The CAPRI Hook Shot Blasting Machine combines innovation, flexibility, and reliability, making it an excellent choice for industries seeking superior surface preparation solutions. With its wide range of models and customization options, CAPRI ensures efficient and consistent results, tailored to your production needs.

Contact us today to learn more about how the CAPRI Hook Shot Blasting Machine can transform your surface treatment process!