|

|

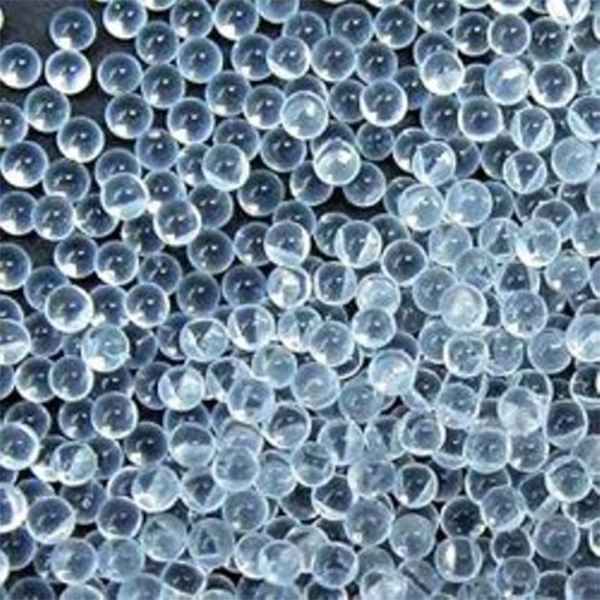

WS round steel shots

|

|

The shots shape in the operating mix

|

round

|

|

Chemical composition

|

carbon ≥ 0,85% phosphorus ≤ 0,05% sulfur ≤ 0,05%

|

|

Medium hardness

|

normally: 450-535 HV / (46-51 HRC)

special: 550-630 HV / (52-56 HRC)

630-720 HV / (56-60 HRC)

|

|

Error

|

at 10 measurements made in the center of the radial section ≥ 2 HRC or ≥ 60 HV1

|

|

Effecive minimum density

|

≥ 7,4 kg/dm³

|

- Metal industries - which represent a world market of more than 1 million tons of abrasives:

- Surface cleaning : in the foundry (sand removal and cleaning of parts), in the forge and stainless steel industry (descaling).

- Surface preparation : cleaning, surface roughening to ensure optimum adherence of paint and coatings.

- Surface enhancement : shot peening treatment against deformation, wear and corrosion.

- Stone industry - which consumes a little over 155 000 tons of abrasives per year: granite cutting by abrasive in a liquid suspension, the abrasive circulates inside gangsaws and is used for cutting stone blocks into thin slabs.

- Other applications have been of use in the mining industry (with Millpebs) and in the building and civil engineering sector (production of WearGrit, a new ultra-high performance concrete based on steel abrasives). Finally, the physical properties of the steel abrasives make it a very interesting material for precision ballasting.

- The round steel shots are used with succes for shotblasting all types of metal surfaces.