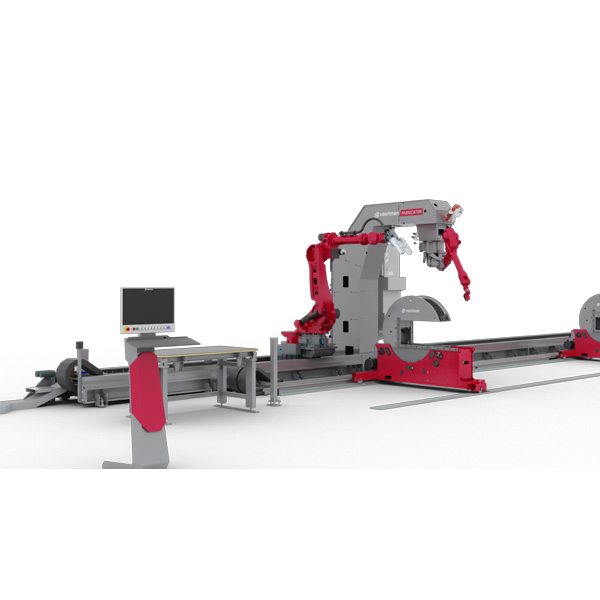

Voortman V807 - Robotic plasma processing machine

The Voortman V807 robotic plasma processing machine is an advanced solution for fabricators looking for high-speed, high-accuracy cutting with a compact footprint. This machine allows for the processing of various geometries directly from raw stock, seamlessly integrating multiple operations such as drilling, milling, sawing, cutting, and weld preparation. Unlike traditional methods that rely on acetylene cutting or mechanical drilling and sawing, the V807 offers unmatched efficiency by combining these functions into a single system, reducing operational costs and increasing productivity.

The Voortman V807 robotic thermal cutting system can handle copes, bolt holes, slots, notches, bevels, weld preparation, and layout marking in a single pass. Its ability to reach all four sides of the material ensures optimal precision and speed. This combination of functionalities eliminates the need for multiple machines, providing an economic advantage and reducing floor space requirements.

Specifications and Technical Data:

- Robotic plasma cutting with full 360-degree rotation (W-axis).

- Fully automated cutting with VACAM software integration.

- Processing capacity for unlimited profile lengths up to 15,000 kg.

- Automatic speed compensation for real-time cutting adjustments.

- Advanced profile measuring system for precision cutting.

- Industry-compliant cutting quality tested under EN1090, ISO3, and AISC standards.

Maximize your production efficiency and cutting precision with the Voortman V807 robotic plasma processing machine. Designed for fabricators who demand high throughput and reliability, the V807 delivers unmatched accuracy, automation, and efficiency. Its compact design and advanced features make it the ultimate investment for businesses looking to optimize their operations.

Contact us today to learn how the Voortman V807 can transform your fabrication process!