TUNNELBLAST Shot blasting machine

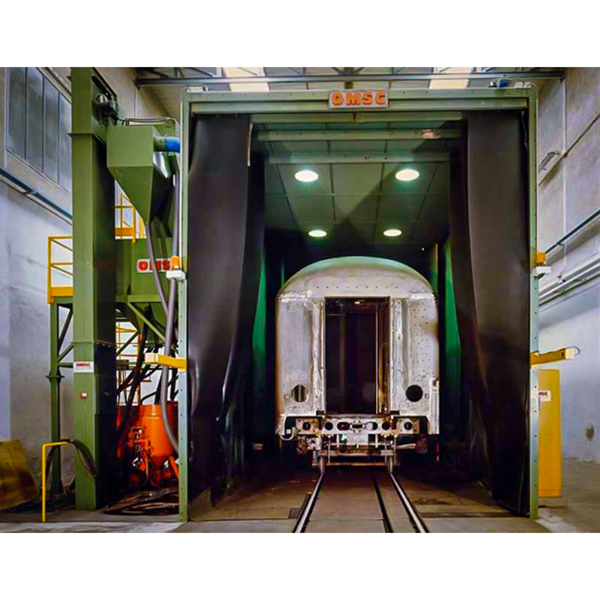

The TUNNELBLAST Shot Blasting Machine is a versatile and powerful system designed for the surface treatment of medium to large-sized products handled horizontally or smaller items suspended on specialized jigs. With its efficient and thorough blasting process, TUNNELBLAST ensures high-quality surface preparation for a wide range of industrial applications.

Key Features of the TUNNELBLAST Shot Blasting Machine

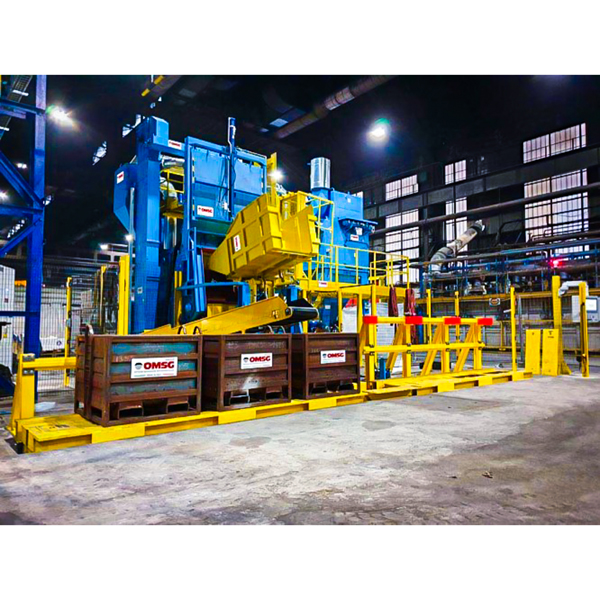

Flexible Handling Options

- Workpieces can be handled using:

- A pair of hoists for lifting and moving.

- Overhead conveyor systems for continuous processing.

- Driven trolleys at ground level for heavy or large items.

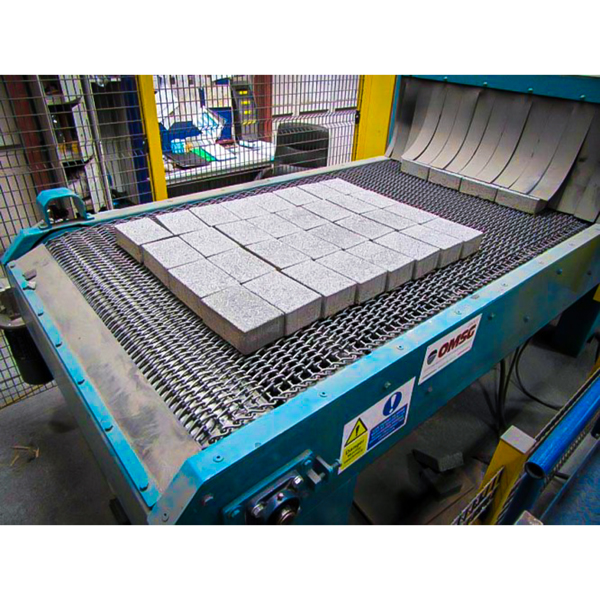

Comprehensive Blasting Process

- The blasting operation is performed in a single pass, covering the entire surface of the component as it moves through the blasting tunnel.

- Optional downstream installations:

- Manual blasting cabinet for detailed retouching.

- Blowing/suction cabinet to remove residual shot from the workpieces.

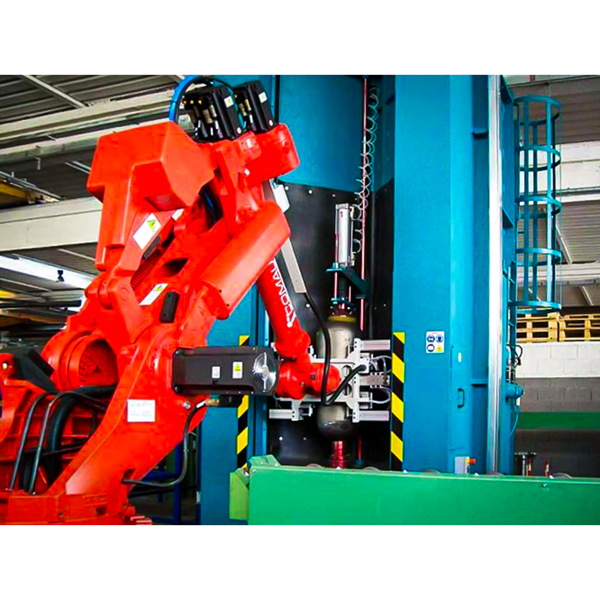

Integration with Automated Systems

- TUNNELBLAST is often integrated into fully automated shot blasting and painting lines, ensuring seamless production workflows and enhanced productivity.

Typical Applications

The TUNNELBLAST Shot Blasting Machine is ideal for treating a wide variety of workpieces, including:

- Structural Steelwork for civil and industrial buildings (sheds, bridges, viaducts, stadiums, warehouses, walkways, platforms, stairs, etc.).

- Agricultural Equipment: Cleaning and preparation for protective coatings.

- Earthmoving Equipment: Surface treatment for durability and performance.

- Road and Building Equipment: Preparing components for long-term use.

- Lifting Machines and Bridge Cranes: Ensuring clean and prepared surfaces.

- Industrial Vehicles and Truck Chassis: Pre-treatment before painting or assembly.

- Railway Trolleys and Metal Tanks: Preparing for protective coatings or assembly.

- Large Castings and Heat-Treated Parts: Ensuring clean, uniform surfaces for finishing.

- Mechanical Components: Preparing parts for integration with painting systems.

Advanced Options

- Manual blasting/blowing room combined with the automatic shot blasting machine for detailed retouching.

- Automatic wheel speed adjustment via frequency electronic control (Inverter).

- Variable delivery shot valve for precise abrasive control.

- Advanced control system using Siemens S7-1200 PLC with an HMI touch screen interface (TP700 COMFORT).

- Digital turbine ampere monitoring for performance tracking and optimization.

- Teleassistance for remote diagnostics and support.

- Automatic refilling unit with a minimum level probe for continuous operation.

Benefits of the TUNNELBLAST Machine

- Versatility: Handles a wide range of product sizes and configurations.

- Efficiency: One-pass blasting ensures complete surface coverage.

- Integration: Easily incorporated into automated production lines.

- Precision and Control: Advanced technology ensures consistent and high-quality results.

- Durability: Built for heavy-duty applications and long-term reliability.

Why Choose TUNNELBLAST?

The TUNNELBLAST Shot Blasting Machine combines flexibility, efficiency, and advanced technology to deliver superior surface preparation for industrial applications. Whether integrated into an automated line or used as a standalone solution, TUNNELBLAST is an essential asset for high-performance production processes.

Contact us today to discover how TUNNELBLAST can elevate your surface treatment operations!