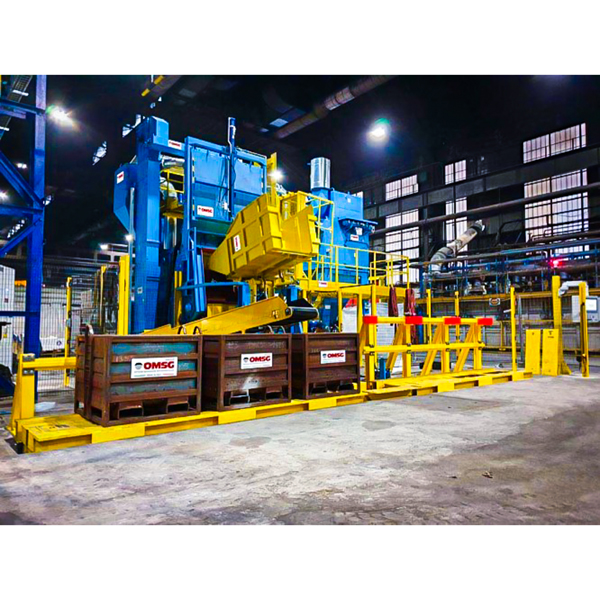

Tappeto Rampante Steel Belt Shot Blasting Machine

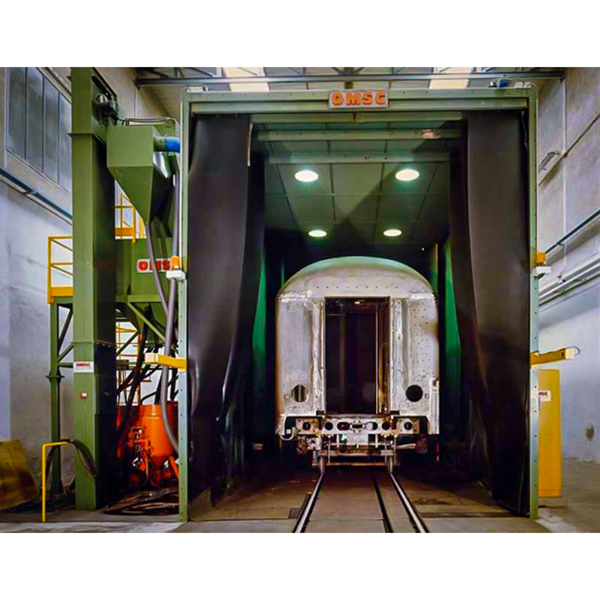

The Tappeto Rampante®, a registered trademark of OMSG, is a robust and versatile solution for the treatment of components in bulk. Designed to handle parts of varying unit weights, it is suitable for a wide range of industrial applications requiring efficient and uniform surface preparation.

Key Features of the Tappeto Rampante® Steel Tumblast Machine

Versatile Capacity

- Accommodates components with unit weights ranging from a few hundred grams up to 250 kg, depending on the machine model.

- Maximum loading weights vary between 600 kg and 3,000 kg, making it suitable for diverse operational needs.

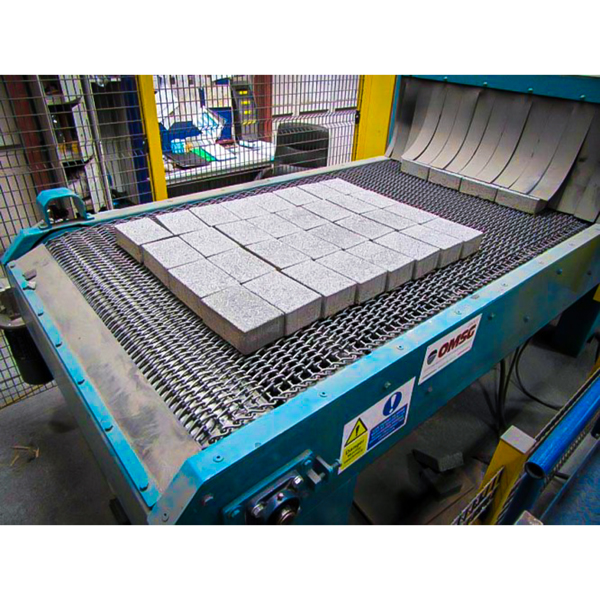

Efficient Shot Blasting Process

- Components are placed loosely on an endless turning belt and evenly blasted by wheels positioned on the roof of the machine.

- Ensures comprehensive surface treatment for each part, regardless of shape or size.

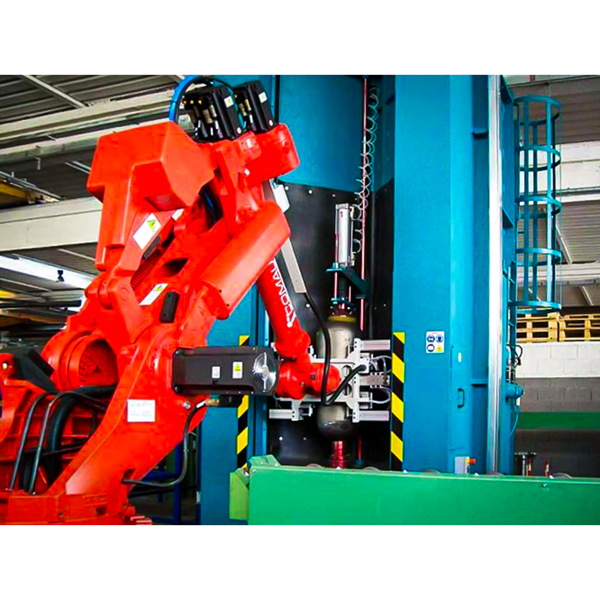

Advanced Loading and Unloading Systems

- Equipped with a hydraulic skip for efficient and safe loading of components.

- Unloading options include direct discharge into a container or onto a vibrating channel that facilitates recovery of residual shot.

Specialized Devices for Optimized Operations

- Magnetic separator for effective removal of unwanted materials.

- Automatic abrasive cleaning device ensures optimal blasting performance, particularly for castings.

Proven Design Expertise

- OMSG pioneered the design and manufacture of Tumblast machines Tappeto Rampante® in Italy, showcasing decades of innovation and expertise.

Applications

The Tappeto Rampante® Steel Tumblast Machine is ideal for the treatment of:

- Cast parts: Brass, cast iron, steel, and aluminum.

- Pressed parts: Steel or brass.

- Forged parts: Durable components requiring uniform surface preparation.

- Heat-treated parts: Components needing surface cleaning after thermal processing.

- Springs: Precision blasting for uniform results.

- Various mechanical parts: A wide range of industrial components.

Advanced Options

- Automatic wheel speed adjustment via frequency electronic control (Inverter).

- Shot valve with variable delivery for precise control of abrasive flow.

- Control system with Siemens S7-1200 PLC and intuitive HMI touch screen interface (TP700 COMFORT).

- Teleassistance for remote diagnostics and support.

- Dust management enhancements: Built-in dust collector and silencer for exhauster.

- Automatic cycle for streamlined operations.

- Special slats for small parts, ensuring optimized handling and processing.

Benefits of the Tappeto Rampante® Steel Tumblast Machine

- Efficiency

- Handles high volumes with consistent blasting performance.

- Automatic systems for loading, blasting, and unloading streamline operations and save time.

- Versatility

- Capable of treating a variety of materials and part types.

- Customizable options to suit specific production requirements.

- Durability and Reliability

- Built with high-quality materials for long-term performance.

- Advanced wear-resistant components reduce maintenance requirements.

Why Choose Tappeto Rampante®?

With a legacy of innovation and quality, the Tappeto Rampante® Steel Tumblast Machine offers unmatched performance for surface treatment. Its versatility, automation, and advanced features make it an indispensable tool for industries seeking efficient and reliable shot blasting solutions.

Contact us today to discover how Tappeto Rampante® can enhance your production line and deliver superior results!