Tappeto Rampante Rubber Belt Shot Blasting Machine

The Tappeto Rampante® Rubber Tumblast Machine, a registered trademark of OMSG, is designed for the efficient treatment of smaller workpieces, with individual weights up to 10 kg. It is the ideal solution for tumbling components, ensuring thorough and uniform surface preparation.

Key Features of the Tappeto Rampante® Rubber Belt Machine

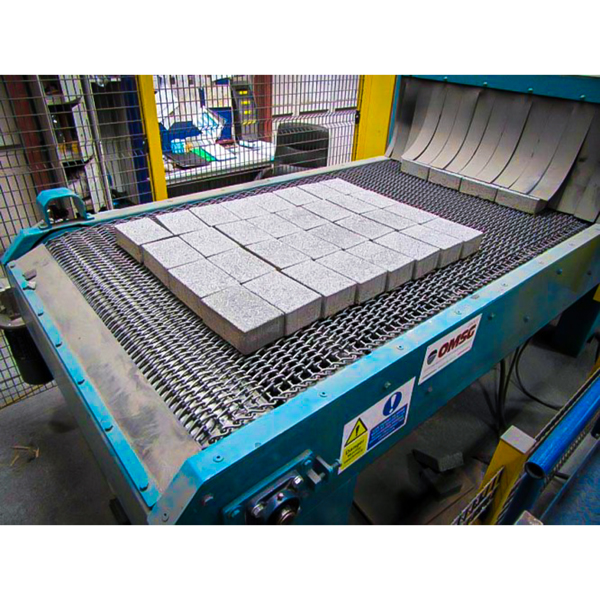

Tumbling Process for Comprehensive Treatment

- Features an endless rubber belt conveyor with high resistance to wear, ensuring durability and longevity.

- Workpieces tumble on the rubber belt as they are blasted by wheels positioned on the roof of the machine.

- Provides even and thorough surface treatment without clustering or damage.

Customizable Configurations

- Equipped with special devices for enhanced finish and precision:

- Frequency converters for belt and wheel speed control.

- PLC system for advanced automation and control.

- Flap and unloading belt to streamline operations and minimize handling damage.

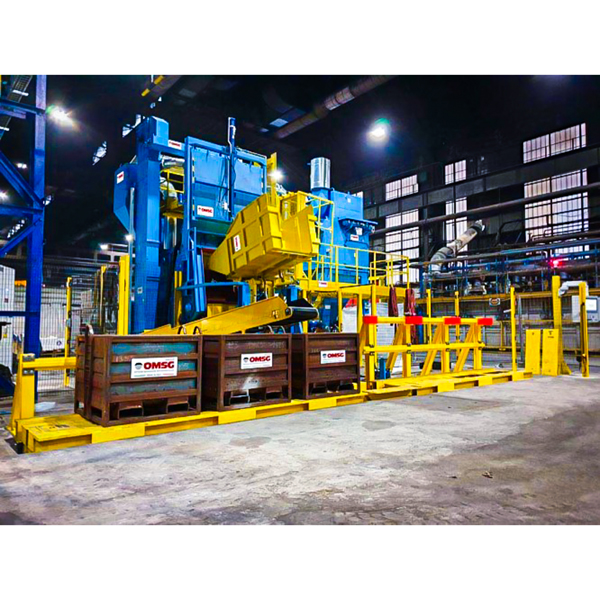

Flexible Loading and Unloading

Loading and unloading can be done:

- Manually, for smaller-scale operations.

- Automatically, using hydraulic skip loaders or vibrating channels for efficient workflow.

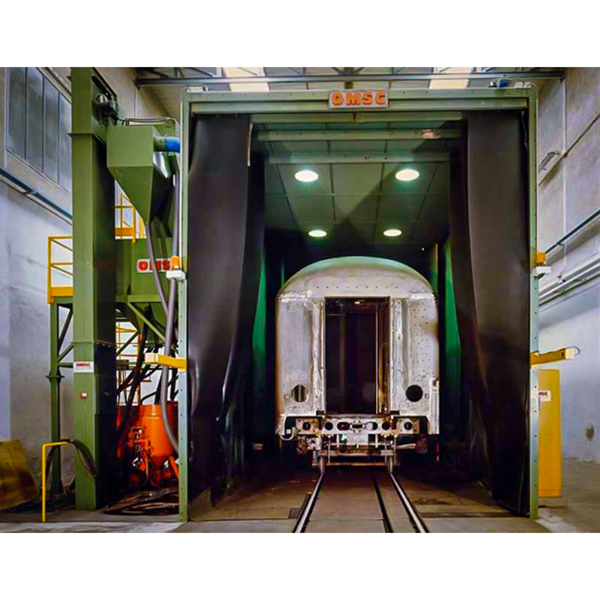

Applications

The Tappeto Rampante® Rubber Belt Machine is ideal for treating a wide variety of components, including:

- Aluminum Die-Castings and Alloys: Used in automotive, furnishing, lighting, telecommunications, and electric tool industries.

- Screws and Bolts: Preparing for subsequent galvanizing treatments.

- Brass and Steel Hot Pressing Parts: Ensuring clean and uniform surfaces.

- Molding Materials (Thermosetting): Prepping for further processing or finishing.

- Various Mechanical Components: Ensuring quality finishes for functional or decorative purposes.

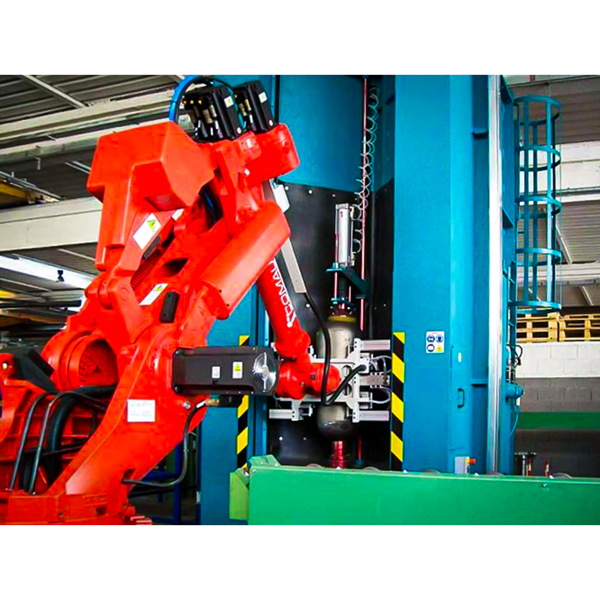

Advanced Options

- Automatic wheel speed adjustment via frequency electronic control (Inverter).

- Shot valve with variable delivery for precise control of abrasive flow.

- Advanced control system with Siemens S7-1200 PLC and intuitive HMI touch screen interface (TP700 COMFORT).

- Teleassistance for remote diagnostics and support.

- Automatic cycle for efficient and streamlined operations.

- Built-in dust collector in select models for improved air quality.

- Workpiece discharging conveyor (vibrating channel) for efficient unloading and recovery.

Benefits of the Tappeto Rampante® Rubber Belt Machine

- Efficiency

- Handles high volumes of small workpieces with consistent and uniform results.

- Automatic systems reduce manual labor and operational downtime.

- Flexibility

- Suitable for a wide range of materials and industries.

- Customizable features allow adaptation to specific production requirements.

- Gentle Handling

- Rubber belt design minimizes the risk of damage to delicate workpieces during the tumbling process.

- Durability and Reliability

- High-quality, wear-resistant components ensure long-term performance with minimal maintenance.

Why Choose Tappeto Rampante®?

The Tappeto Rampante® Rubber Belt Shot Blasting Machine is the perfect combination of efficiency, precision, and reliability. Whether you need to prepare small aluminum castings, screws, bolts, or various mechanical components, this machine ensures top-tier results with minimal handling damage.

Contact us today to discover how Tappeto Rampante® can optimize your surface treatment processes and enhance your production line!