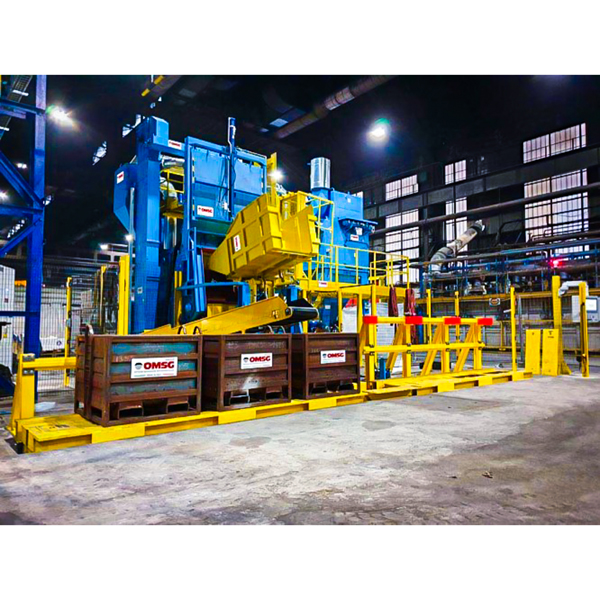

CWB Shot blasting machine with steel wire mesh conveyor

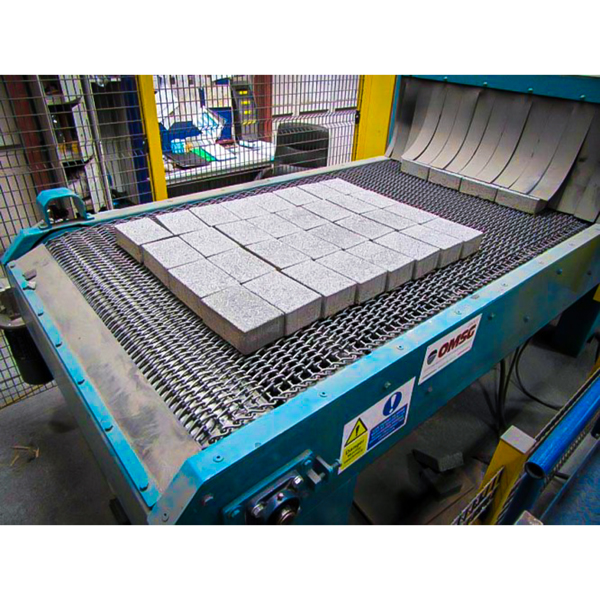

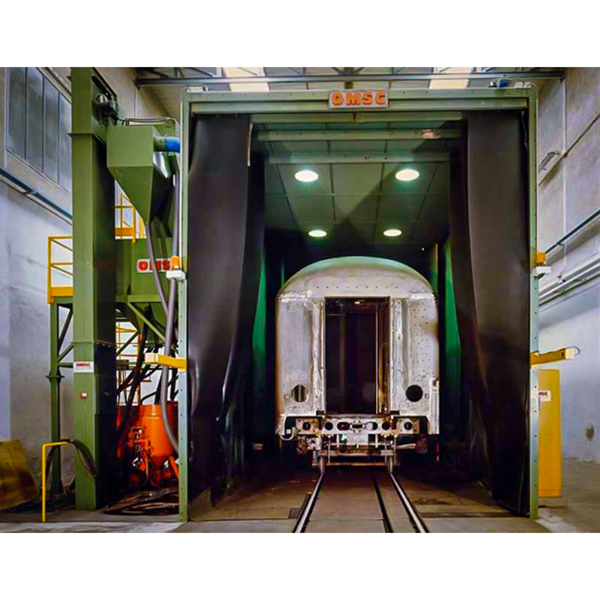

The CWB Shot Blasting Machine is an automated, high-productivity system designed for the efficient surface treatment of a wide range of materials. Utilizing a durable steel wire mesh conveyor, the machine ensures thorough shot blasting of workpieces both above and below in a single pass through the blast chamber.

Key Features of the CWB Shot Blasting Machine

Efficient Surface Treatment

- Workpieces are placed on a high-wear-resistant steel wire mesh conveyor, ensuring durability and longevity.

- The blasting process cleans both the upper and lower surfaces of the components in one efficient pass through the blast chamber.

Adjustable Process Parameters

- The speed of the wire mesh conveyor and the rotation of the blast wheels can be adjusted using a frequency electronic control Inverter, allowing for precise control of the treatment process.

- Multiple models are available, with passage widths ranging from 500 mm to 1,500 mm, accommodating various production needs.

Flexible Loading and Unloading

Workpieces can be loaded and unloaded:

- Manually, for smaller operations.

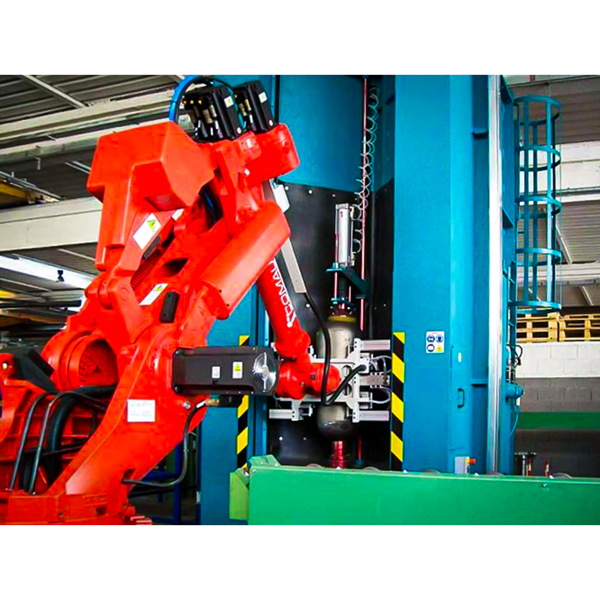

- Automatically, through transport systems or robots integrated before and after the conveyor, enhancing productivity.

Wide Range of Applications

The CWB Shot Blasting Machine is ideal for continuous treatment of:

- Aluminum Die-Castings and Alloys: Used in automotive, alimentary, furnishing, lighting, telecommunications, and electric tools industries.

- Oxygen-Flame Cutting Parts: Preparing components for further processing.

- Cast Iron Parts: Cleaning and surface preparation.

- Steel Pressing Pieces: Ensuring uniform surface finishes.

- Brass Molded Pieces: Preparing for decorative or functional coatings.

Advanced Options

- Automatic wheel speed adjustment via frequency electronic control (Inverter).

- Shot valve with variable delivery for precise control of abrasive flow.

- Control system featuring Siemens S7-1200 PLC with an intuitive HMI touch screen interface (TP700 COMFORT).

- Teleassistance for remote diagnostics and support.

- Automatic recovery and recycling of shots, reducing waste and operational costs.

- Kick-off roller for efficient unloading of workpieces.

- Special belts designed for piece recovery, enhancing operational efficiency.

Benefits of the CWB Shot Blasting Machine

- High Productivity: Continuous operation and automated handling increase throughput.

- Flexibility: Adjustable parameters and various models cater to diverse industries and material types.

- Precision and Uniformity: Advanced control systems ensure consistent surface treatment quality.

- Durability: Steel wire mesh conveyor and wear-resistant components enhance machine longevity.

Applications

The CWB Shot Blasting Machine is extensively used in industries such as:

- Automotive: Surface preparation for critical components.

- Aluminum and Brass Manufacturing: Cleaning and finishing parts for decorative and functional purposes.

- Steel and Cast Iron Processing: Ensuring clean and uniform finishes for industrial components.

- Telecommunications and Electric Tools: Preparing surfaces for protective coatings.

Why Choose the CWB Shot Blasting Machine?

Combining efficiency, versatility, and advanced technology, the CWB Shot Blasting Machine delivers superior results for high-demand surface treatment applications. Its flexible configurations and customizable features make it the ideal choice for businesses seeking quality and productivity.

Contact us today to learn more about how the CWB Shot Blasting Machine can revolutionize your surface treatment process!