Main Electric Box Hall

The electric box for the painting-drying booth is assembled in a Rittal steel case with electric devices Eaton, SchneiderTelemecanique, Siemens. The command and control for the blasting, painting and drying operations is made with a Siemens microcontroller S7. Carefully developed software ensures optimum operation of the equipment. The electric box is manufactured in accordance with the standards EN 60204-1, EN 50081-1, EN 50081-2.

The electric box is designed to command and control equipment for 2 halls:

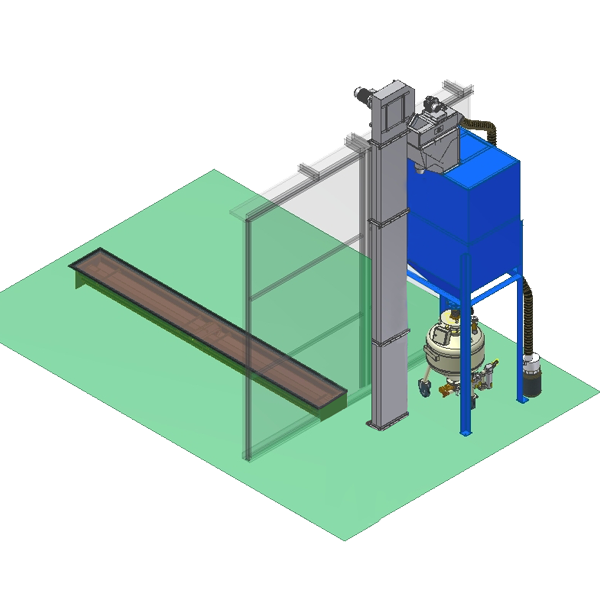

- abrasive recovery equipment (cleaner, dust filter for cleaner, elevator, V-Belts)

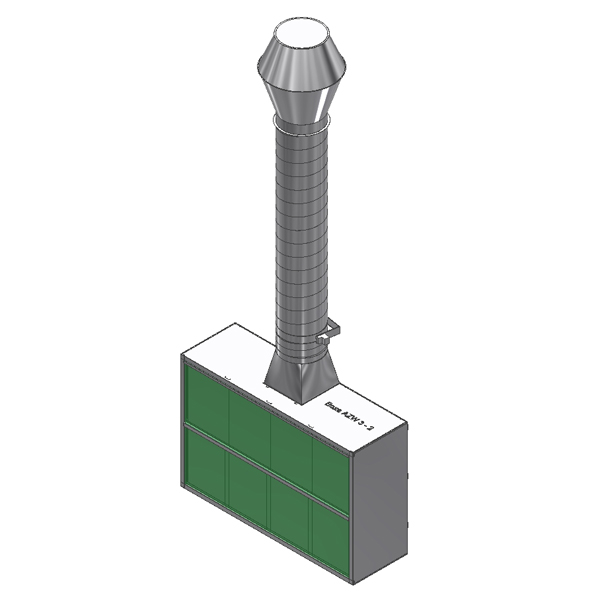

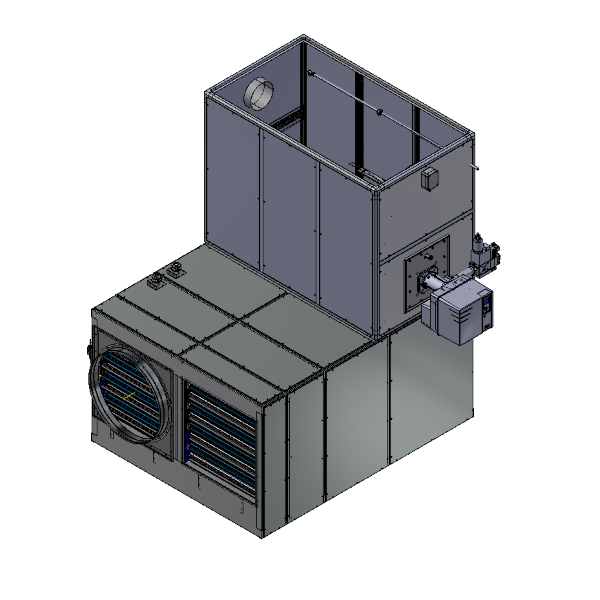

- 4pcs electric boxes for supply and exhaust units TSV

- 4pcs electric boxes dust filters for ventilation

The safety system is wired, data transfer by profinet.

Following functions are designed:

- Start-stop devices in automatic mode, ventilation prepare blasting, blasting, prepare painting, drying

- Start-stop devices in automatic mode, abrasive recovery.

- Manual mode for service reason (supply and exhaust units TSV)

- Monitoring faults, total hours, silo level, etc.

- Monitoring hall humidity and temperature, outside humidity and temperature, LeL level when painting/drying

- Parameter changing (with user name and password)

- Profinet data exchange with equipment local electric boxes

Ask our experts!