Polishing solutions for concrete surfaces

14.06.2017

Polishing concrete surfaces implies a soft and progressive grinding of them. This can be done while using a triple head grinder with diamond disks and grinding plates with progressive granulation. Usually it is admitted that the concrete is not polished unless a 400 granulation is used and the optimum results can be obtained at granulations of 800, 1500 and 3000.

For improving the final results it is recommended to paint the surface after polishing it.

BLASTRAC offers complete solutions for perfect results. Usually the concrete has to be treated in the first 24 up to 48 hours from pouring it. Based on its initial color, its size and texture one can opt for the most appropriate polishing equipment in order to get the desired type of finish (including the aspect of marvel).

The polished concrete is considered a reasonable floor design solution. Furthermore, the surfaces that are treated this way do not imply special maintenance costs as they resist on long term and can be easily cleaned. The polished concrete has a 100 years longer lifetime than any other type of floor.

They are the perfect solution for retail spaces, office buildings and public areas.

The technic is also adopted in civil constructions mainly due to the possibility to obtain special types of finishings such as the marvel aspect or the polished stone one.

The polishing operation can be organized both in dry and wet formats, depending on the existing situation on the site. If the dry version is chosen it is recommended to combine the grinding machine with an industrial vacuum cleaner so that the dust resulted during the operation gets collected. BLASTRAC offers also this equipment for a better compatibility.

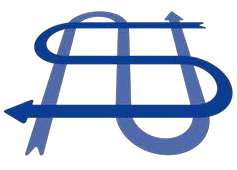

It is important that during the process one considers working with the machine passing the surface as presented in the following scheme.