Metallization – the quality guarantee for long term protection of metal parts

28.03.2017

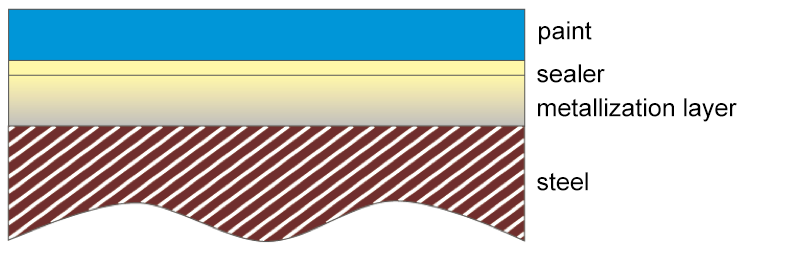

During surface treatment processes, the layers added on a metal part while metallizing it after blasting and before painting procedures, will extend the lifetime of the protection system from 10 to 30 years.

The intermediary layer applied through metallization insures:

a better mechanical resistance of the protected surface

more resistance to humidity and to the hot and cold fluctuations

the possibility the configure the protection system of metal components in accordance to the expected mechanical and chemical influences onto the parts

The procedure can be also used when willing to repair series of imperfections like for instance when needing to add an extra layer onto some particular areas of the metal surface in order to level it.

Why is metallization an advantageous procedure on long term?

Metallization allows configuring the protection system based on the influences the metal part will be subject to. From this point of view the procedure is more flexible than any other alternative solution. Furthermore, as long as metallization is offering a long-term quality guarantee, it allows experiencing a relevant reduction of maintenance costs of the metal structure.

Beside the fact that metallization is offering long-term protection to the metal surfaces it also represents a method with positive impact on the natural environment. The waste resulted during the process is just a dust which can be collected through the filters of the ventilation system. This is afterwards packaged in sacks and deposited at the recovery units.

The metallization workshop

Organizing a metallization unit is easy to be done and needs only:

adding a compatible ventilation system

ATEX lights

compressed air connectivity

connectivity to the electric or gas source

The expected production capacity is the one determining the size of the metallization workshop and the choice related to the adequate ventilation solution. The metallization equipment is configured based on the overall possibilities of the metal parts’ producer and on the size of the components to be processed.

When choosing the right equipment one should also take into consideration the recommendations related to the necessary waiting time between different operations (blasting, metallization, and painting).

Usually the machines are able to apply layers of minimum 0.05 mm and maximum 0.4 mm during one pass.

For the perspective of anticorrosive protection, no matter which machine will be used for metallization purposes, there will be no structural modifications or alternations of the processed metal parts.

The metallization equipment is designed not only for workshops, but also for being used on large sites and shipyards, for both new production or repair works.

Actually any parts bigger than 10 cm can be processed in good conditions from both expenses and productivity points of view.

Training the stuff to work with the metallization equipment is also easy done as long as the operators are selected from the welders.