Electrostatic painting

24.04.2017

In case of electrostatic painting the atomization of paint takes place in an electric field, at the end of the painting gun. Immediately after, the particles getting out thorough the nozzle are positively charged.

Therefore the surface to be treated, which has a lower potential, attracts the paint like a magnet.

The major advantages of this technology are represented by the lower emission of volatile organic compounds and by the fact that the transfer of paint is 60 to 70% more efficient than in case of air spraying. The productivity increases and the paint consumption decreases considerably.

Even if the electric charge of the paint is a low one, it is still strong enough for counterpartying the aerodynamic and gravity effects. In fact the attraction force is 75 times bigger than the gravity, which makes it possible for the paint particle to get fixed on the metal surface. This is also achievable because the chemical compounds existing in paints that are destined to electrostatic application, are poorly conductive.

GRACO developed a large product palette, able to insure an operating voltage of 40 kW. Both standard and SMART versions are available. With an integrated compressed air generator the voltage can go up to 85 kW. This allows the use of the equipment without needing an extra electric source.

Short technologies’ comparison

| Airspray | Air assisted |

| Best finish quality | Best transfer efficiency |

| Allows controlling the paint debit | The layer size and the debit are determined by the size and the angle of the nozzle during application |

| The silting possibility is diminished | High level of productivity, but also risk of silting |

| Settings foor atomization and spray air are available | More efficient for conductive paints |

Factors influencing the transfer efficiency of the paint

- the distance between painting gun and surface to be treated (recommended: 250-300 mm)

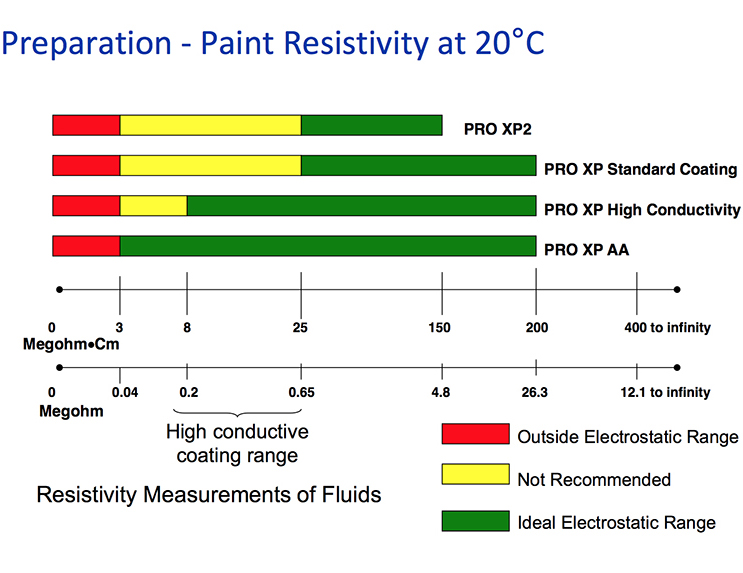

- paint conductivity

- form of the object to be painted

The control of the paint conductivity can be organized using a simple check instrument which displays in different colors format if the paint can be applied using the electrostatic technology. When the indicator is green the best results can be obtained.

Perfect choose of the right type of equipment based on the resistance of paint at 20°C

Security aspects

Ground fault is mandatory when electrostatically painting. All conductive elements are to be considered, including the operator. He will have to wear special gloves and boots. The spraying gun itself, the object to be painted, the paint pots, the painting pumps and the air hoses, all have to be ground faulted.